Why does high brightness become an important trend in the laser industry?

As laser cutting penetrates into high-end manufacturing fields such as automobile manufacturing and aerospace, lasers will gradually move from power first to an era of equal emphasis on power and brightness. Because high power determines the processing capacity and cutting thickness, but it cannot guarantee the cutting quality; High brightness means higher precision and higher quality, which can avoid excessive energy loss in the cutting process and achieve cost reduction and efficiency increase.

BWT has conducted in-depth research on the performance improvement of high-power fiber lasers, and launched a high-brightness quasi-single-mode 6KW optical platform to achieve performance upgrades, taking into account both efficiency and quality, and is expected to become a sharp tool for ultra-high-power fiber laser air high-speed cutting in the future.

High-brightness quasi-single-mode 6KW optical platform

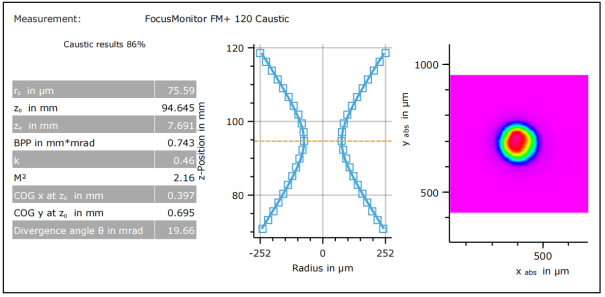

The beam quality M² reflects the degree of focus of the beam in the optical system and the degree of focus during transmission. The smaller the M², the higher the beam focus, the greater the energy density, and the better the beam quality.

The beam quality factor of 6~10kW industrial multimode lasers on the market is generally M²≈ 10 – 11. Relatively speaking, the high-brightness quasi-single-mode 6KW optical platform has better beam quality, and the laser beam can be focused close to the diffraction limit: the output fiber core diameter of traditional multi-mode 6000W continuous fiber lasers is mostly 100μm and 75μm output, but 50μm and below are more difficult. The high-brightness quasi-single-mode 6KW optical platform breaks through this bottleneck and realizes 34μm high-brightness quasi-single-mode output.

The average energy density is more than 8 times that of multi-mode lasers.

Compared with the traditional multi-mode 6KW continuous fiber laser with 100μm core diameter output, the cutting efficiency is significantly improved. The high-brightness quasi-single-mode 6KW optical platform can achieve 34μm laser output, and is compatible with 50μm and 100μm output at the same time, meeting the cutting application needs of different customers, effectively saving users’ comprehensive operating costs, and promoting the upgrading of laser cutting downstream industries.

Stable performance, compact and portable

Based on the Lightning series highly integrated structure design and the fourth-generation pump source technology, the performance of the whole machine is effectively improved:

The electro-optical conversion efficiency of the whole machine can reach more than 40%, saving energy and reducing consumption;

Multiple anti-high anti-reflex structure design, the anti-aging ability is greatly improved;

Highly integrated structure, richer application scenarios;

With host computer control, Bluetooth control, DB25, DB9 and other control functions and interfaces.

Ultra-high-power beam-combining fiber lasers will be widely used in the future national economy, and are suitable for cutting, welding, cladding, cleaning and other scenarios of various metals and plates.

Facing the application requirements of ultra-high-power fiber lasers in the future, the high-brightness quasi-single-mode 6KW optical platform can effectively solve the defects of ultra-high-power fiber lasers such as poor output beam quality, low stability, redundant volume, and bulkiness. the

In the ultra-high-power combined beam fiber lasers to be launched by BWT Thunder series, the high-brightness quasi-single-mode 6KW optical platform will be used as the core component and will play an important role in future laser processing, creating greater value for China’s high-end manufacturing .

Post time: May-12-2023